Fundamentals

The CER™ System: An Overview

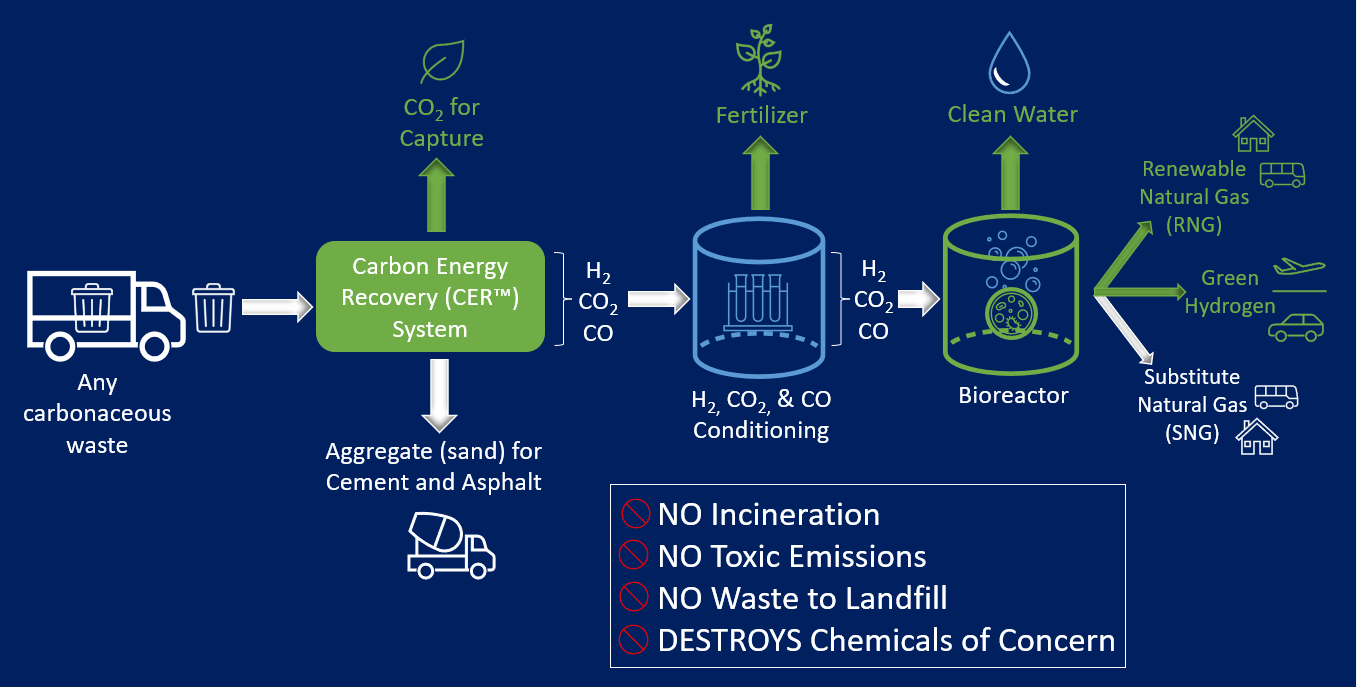

BRADAM’s patented CER™ System and facility design provide an environmentally responsible way to divert any carbonaceous materials from landfills and convert them into pipeline grade Renewable Natural Gas (RNG), Green Hydrogen (GH2), and Substitute Natural Gas (SNG). Byproducts like biogenic carbon dioxide for capture, fertilizer, inert aggregate used in the production of asphalt and cement, and clean water are produced during processing as well.

Our system is combustion-free and yields a high quality energy, making it a radical departure from existing waste to energy processes.

Waste is a terrible thing to waste.™

The CER™ System can process any carbon-based material, including but not limited to the following:

Biogenic Carbon Waste:

(to make Renewable Natural Gas & Green Hydrogen)

- Food residuals from commercial and residential sources

- Biosolids from wastewater treatment facilities

- Digestate from anaerobic digesters

- Wood biomass

- Dried distiller’s grains

Fossil Carbon Waste:

(to make Substitute Natural Gas)

- Municipal solid waste (“MSW”)

- Non-hazardous commercial wastes (plastics)

- Non-hazardous industrial waste

- Special industrial waste (tires, paint)

Learn How Our CER™ System Converts Any Carbonaceous Waste to Useable Energy:

Fundamentals

The CER™ System's Modular Design

The modular design of our system allows us to match the size of the production capacity to the needs of the area we are servicing. Each module has redundancy and uses components that are readily available from our manufacturing partners.

Annual Input per module

100,000 tonnes per year of process-ready feedstock

Annual Outputs per module

≈1,200,000 gigajoules of energy

≈12,000 tonnes of inert aggregate

≈50,000 liters of water

Contact us to estimate energy production and other products derived from your specific project feedstock.

We Solve Waste Problems

With Energy Solutions

In all four corners of the world waste is polluting our lakes, oceans and the air we breath. Traditional ways of dealing with waste are antiquated, expensive and have a negative effect on our environment. There is a better way.

BRADAM Energies' Carbon Energy Recovery (CER™) System creates energy from waste using a Canadian developed revolutionary process that is highly efficient, economical and environmentally friendly.

Not only do we solve the world’s waste problems; we create energy in the form of Renewable Natural Gas (RNG), Green Hydrogen, or Substitute Natural Gas (SNG).

WASTE is a terrible thing to waste.™